Komax AG

Trust, quality, global logistics

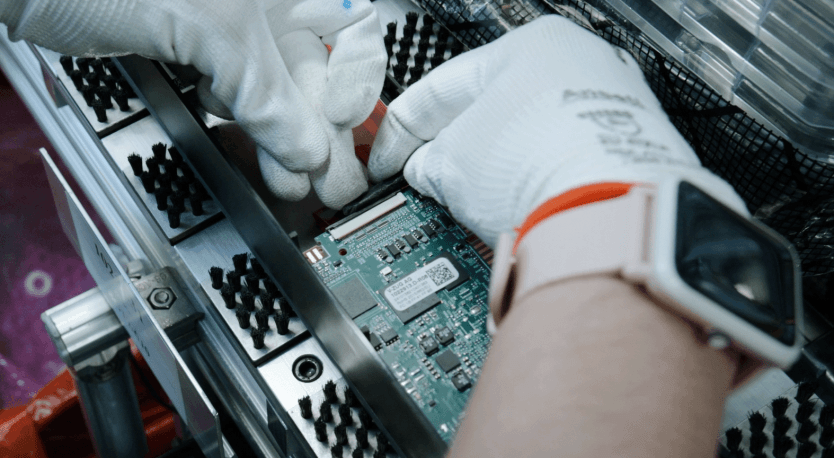

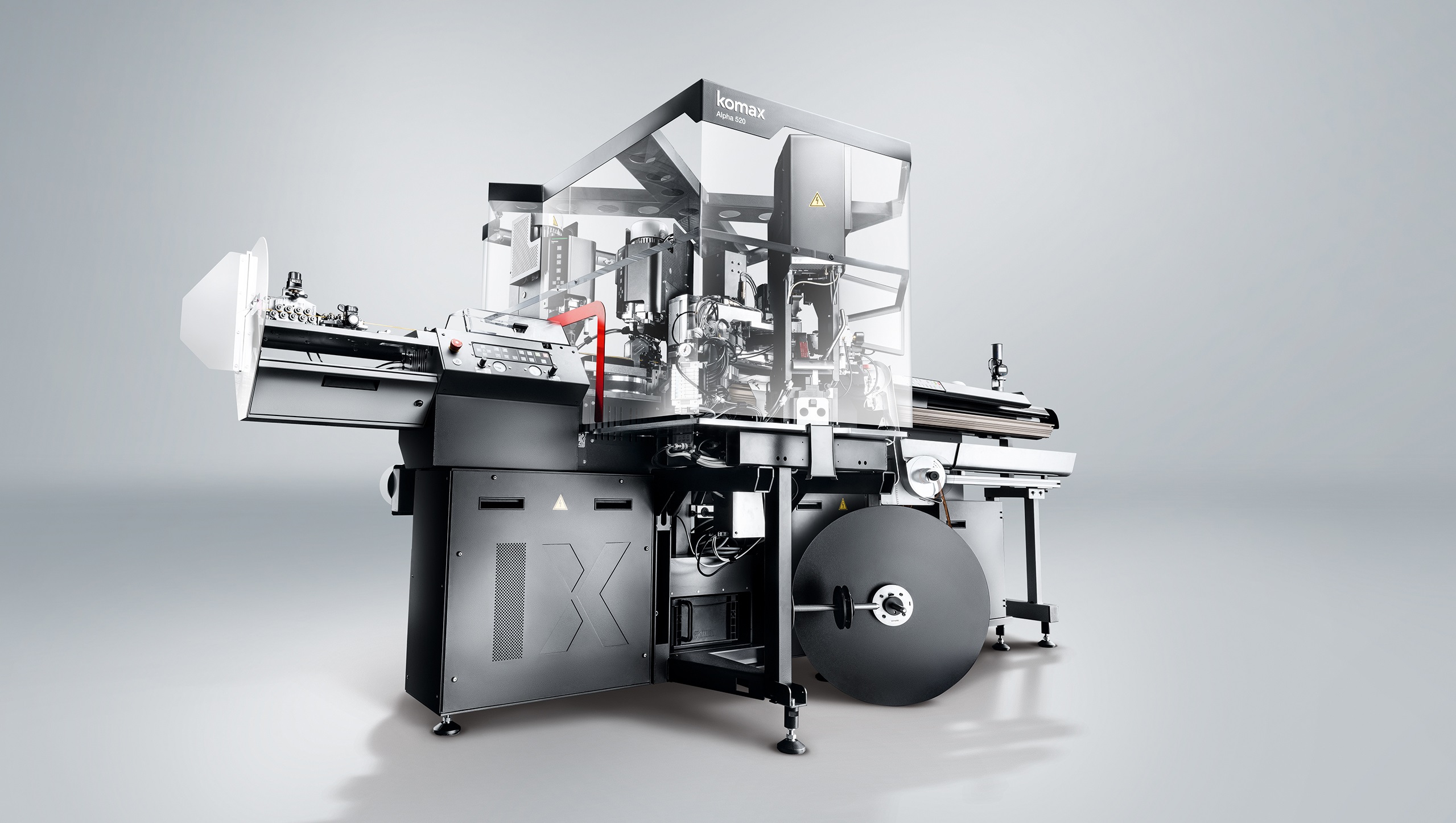

For the electronic components of its fully automated wire processing machines – including servo controllers weighing up to 5 kilograms and robust display units – Komax has long relied on Variosystems. What began as a local collaboration in the early 1990s has evolved into a technology partnership supported by world-class global logistics.

"We expect our EMS partners to actively contribute – especially by identifying better, more cost-effective and available alternatives for critical components."

Komax AG

Headquartered in Dierikon, Switzerland, Komax is a global market leader in automated wire processing. The company develops and manufactures both standard and customer-specific machines with varying levels of automation. Its portfolio is complemented by quality assurance modules, testing devices, and intelligent networking solutions to maximize flexibility and efficiency in production. With around 3,500 employees and a presence in over 60 countries, Komax primarily serves the automotive supply industry through a global sales and service network.

130

5kg

4 days

30+ years

130

5kg

4 days

30+ years

Complexity meets clarity

For up to 1,000 wire processing machines that Komax produces each year – from standard solutions to highly customized systems – we supply around 130 different PCBs and assemblies. These range from compact boards made in Sri Lanka to sophisticated servo controllers weighing up to five kilograms, assembled in Croatia from multiple boards, housings, and cooling units.

Stronger together: Komax and Variosystems

"Variosystems has been with us since we started integrating electronics into our machines – that was in the early 1990s," says René Theiler, Strategic Buyer Electronics at Komax. Today, Variosystems is one of three preferred EMS partners worldwide, with an annual order volume of around five million Swiss francs. Key factors include their global presence, professional team, obsolescence management, cost transparency, and a close working relationship with a small number of dedicated contacts.

From Sri Lanka to Croatia to Switzerland

Variosystems’ global setup offers a decisive advantage for Komax, as René Theiler explains: “Opening the site in Sri Lanka was a turning point. We operate globally, especially in Asia and particularly in China – so we need a partner that does the same.” A large share of PCBs is produced in Sri Lanka – many are shipped directly to Komax’s site in China, others go to Switzerland, Turkey, or Germany. Some units are further processed in our box-build competence center in Croatia, where housings and heat sinks are added. Final functional testing is performed using a Komax-specific testing tower before the assemblies are shipped to Dierikon (CH) for final integration.

Delivery at the push of a button

Logistics are tightly integrated: an automated ordering process via Komax’s ERP system triggers a weekly order every Tuesday. By Friday at 6 a.m., the shipment is delivered to Dierikon – just-in-time, without paper or PDFs.

Reliable service across the entire product lifecycle

“Variosystems is fast, responsive, transparent and understands our needs,” emphasizes René Theiler. This is built on regular, direct communication and a deep mutual understanding – both technical and personal. Challenges are addressed openly and solved collaboratively, with the aim of ensuring stable processes and uninterrupted supply chains. The Variosystems Customer Success Team supports Komax with comprehensive services across the entire product lifecycle: design-to-cost, design-to-supply, obsolescence management, global supply chain, and test engineering. Thanks to this close collaboration, tailored solutions are created – efficient, robust, and scalable.

Future-ready

Risk management is a top priority for Komax. We stock strategic components on behalf of Komax, ensuring supply even in times of crisis. “Unlike our competitors, we had access to critical components throughout the pandemic – saving us several million Swiss francs,” says Theiler. Komax deliberately partners with EMS providers who are proactive – whether it’s optimizing BOMs, replacing components, or identifying cost-efficient alternatives. Alongside technical expertise, ESG factors such as EcoVadis certification, strict payment terms, and transparent pricing also matter. The strategy is clear: few partners, strong relationships, and a shared understanding of quality, reliability, and future resilience.

In conversation with René Theiler, Strategic Buyer Electronics at Komax

We’re streamlining procurement and focusing on a carefully selected group of high-performing global EMS providers. The strategy is to increase transparency and efficiency by working with fewer, stronger partners. Variosystems is one of just three preferred suppliers worldwide.

We expect proactive input – especially when it comes to finding better, more cost-effective, and readily available alternatives for critical components. BOMs must be fully transparent, including pricing, so we can benchmark fairly. In some cases, we negotiate Komax-specific prices directly with manufacturers. We also require buffer stock – risk management is non-negotiable for us.

We classify components into four categories and maintain safety stocks for sensitive parts – with coverage ranging from 12 to 36 months. This means we can remain operational for up to three years, even in the event of a disaster. As far as I know, none of our competitors take risk management to this level.

Absolutely – during the pandemic, it paid off in full. We could deliver critical components when others couldn’t.

Variosystems has been with us since the beginning – when we first introduced electronics into our machines in the early 1990s. Back then, proximity and shared language were key. Today, we benefit from global reach and a high level of professionalism.

Sri Lanka was a key milestone. We’re active globally, especially in Asia and China – and we need a partner who is too. Variosystems manufactures most of our products in Sri Lanka – many go straight to our facility in China, others to Switzerland, Germany or Turkey.

Some products go through final assembly in Croatia, where housings and cooling elements are integrated and testing is done using our own test towers. Their global setup also gives us financial stability, as we operate in both CHF and USD – minimizing currency and exchange rate risks.

It’s been defined by openness and trust for many years. Our contacts are true professionals – many have been with us for a long time. The introduction of the Customer Success Teams took things to another level: a single point of contact, fast response times, transparency, and a genuine understanding of our needs – that’s exactly how it should be.

We hold quarterly synergy meetings, work through open topics, and collaborate closely on engineering. We also evaluate suppliers regularly – including on ESG criteria. Participation in EcoVadis and ongoing improvement is a must. That’s a clear expectation from our customers in the automotive sector.

我们使用 Cookie 来提升您在我们网站上的体验。如果您继续浏览或点击“继续而不授权”,将仅使用技术上必要的 Cookie。点击“接受所有 Cookie”,即表示您同意使用营销 Cookie。您可以在“Cookie 设置”中调整您的偏好。更多信息请参阅我们的隐私政策。

Cookie 设置

我们使用 Cookie 以确保我们网站的基本功能。您可以为每个类别选择接受或拒绝 Cookie。

我们使用 Cookie 以确保我们网站的基本功能。您可以为每个类别选择接受或拒绝 Cookie。

这些 Cookie 使您和我们能够使用网站的基本功能。它们对于网站的正常运行至关重要。

- 机器人/垃圾信息检测

- YouTube 嵌入内容

- 语言选择

- 表单的服务器会话处理

- CSRF/身份验证

- 其他基本功能 Cookie(例如用于导航和安全的会话 Cookie)

功能性 Cookie 允许在我们的页面中集成外部内容,您无需离开我们的网站即可使用这些内容。

- 布局偏好设置

- 新闻订阅表单 Cookie(Mailchimp 用于订阅管理)

营销 Cookie 允许我们通过外部平台提供个性化广告和再营销服务。我们使用这些 Cookie 来持续优化我们的服务,并根据您的需求进行调整。

Google Tag Manager

Google Analytics

Google Ads

Google Ads 再营销

Google 转化跟踪

Microsoft Clarity

Meta Pixel

LinkedIn Insight Tag

Mailchimp

保护您的个人数据对我们来说非常重要。更多信息请参阅我们的隐私政策。

Sign up for our newsletter

We look forward to sending you regular information on what is happening at Variosystems.